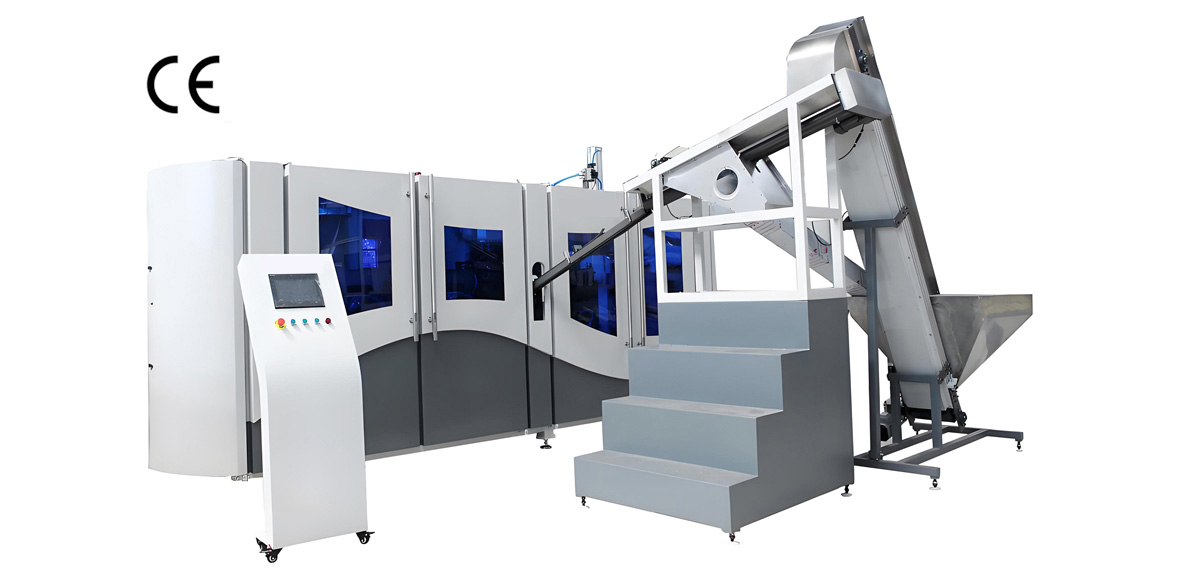

Máy thổi chai PET tốc độ cao

Price

Contact Us For A Quote

Dịch vụ sau bán hàng

7*24 Hours

Payment Method

T/T or L/C

Transportation Method

By Sea

Tips: We have many models of machines, and there are also many machine parameters involved. Due to different voltage standards in different countries, we suggest that you can consult us directly online or send us detailed requirements.

Description

FG series bottle-blowing machine, whose single-mold speed can reach 2500~3000BPH. FG series bottle-blowing machine includes three models right now: FG4 (4-cavity), FG6 (6-cavity), and FG8 (8-cavity), and the max speed could be 15000BPH.

High-speed machine FGX series blow molding machine, single-mode speed can reach 2500~3000BPH. FGX series blow molding machine currently includes three models: FGX4 (4 cavities), FGX6 (6 cavities), and FGX8 (8 cavities), the maximum speed can reach 20000BPH. This series of models mainly produces PET plastic bottles, pure water, mineral water PET bottles, and beverage bottles. It is developed totally independently, has our own intellectual property rights, and has obtained more than 13 patents.

FG series bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power, and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise, and high stability, meanwhile conforming to chinese beverage sanitary standards. This machine symbolizes the highest level of chinese linear blowing machines. It is the ideal bottle-making equipment for medium and large enterprises.

Capacity

| Model | Capacity |

| FG4 | 6500-8000 BPH |

| FG-4X | 8000-9000 BPH |

| FG6 | 9000-10000 BPH |

| FGX6 | 12000-13000 BPH |

| FG8 | 12000-13000 BPH |

| FGX8 | 15000-16000 BPH |

Parameters

| Model | FG4 | FGX4 | FG6 | FGX6 | FG8 | FGX8 | ||

| Mold number(pcs) | 4 | 4 | 6 | 6 | 8 | 8 | ||

| Capacity (BPH) | 6500-8000 | 8000-9000 | 9000~10000 | 12000-13000 | 12000~13000 | 15000-16000 | ||

| Bottlespecification | Max volume(ml) | 2000 | 750 | 750 | ||||

| Max height(mm) | 328 | 290 | 300 | |||||

| Round bottle max diameter(mm) | 105 | 75 | 75 | |||||

| Square bottle max diagonal(mm) | 115 | 75 | 75 | |||||

| Preform specification | Suitable inner bottle neck(mm) | 20–25 | ||||||

| Max preform length(mm) | 150 | 140 | 150 | |||||

| Electricity | Total installation power(Kw) | 51 | 51 | 51 | 97 | 97 | 97 | |

| Heating oven real power(Kw) | 25 | 32 | 30 | 42 | 45 | 48 | ||

| Voltage/frequency(V/Hz) | 380 (50Hz) | |||||||

| Compressor | Capacity | 4 | 6 | 6 | 8-10 | 8 | 10 | |

| Pressure (bar) | 30 | |||||||

| Cooling water | Mold water | 4–6bar | ||||||

| 6–13°C | ||||||||

| Oven water | 4–6bar | |||||||

| 6–13°C | ||||||||

| Machine specification | dimension(m)(L*W*H) | 3.3*1.0*2.3 | 4.0*1.3*2.2 | 4.3*1.0*2.3 | 5.5*1.3*2.5 | 4.8*1.0*2.3 | 5.5*1.3*2.5 | |

| weight(Kg) | 3200 | 3500 | 3800 | 6500 | 4500 | 6500 | ||

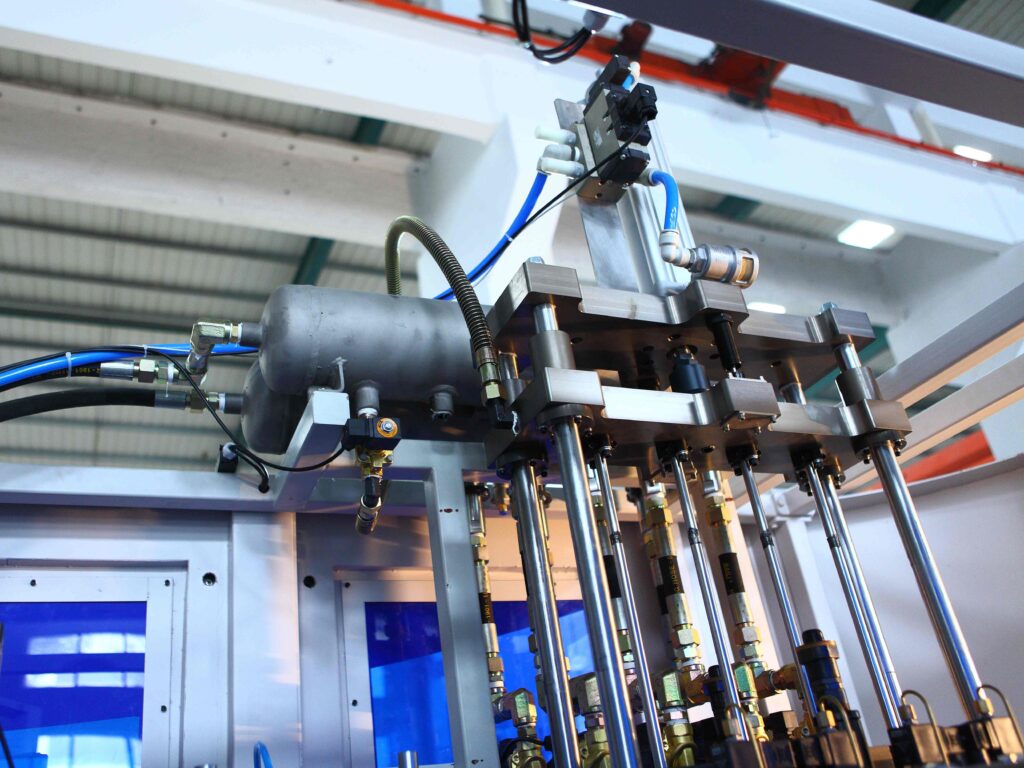

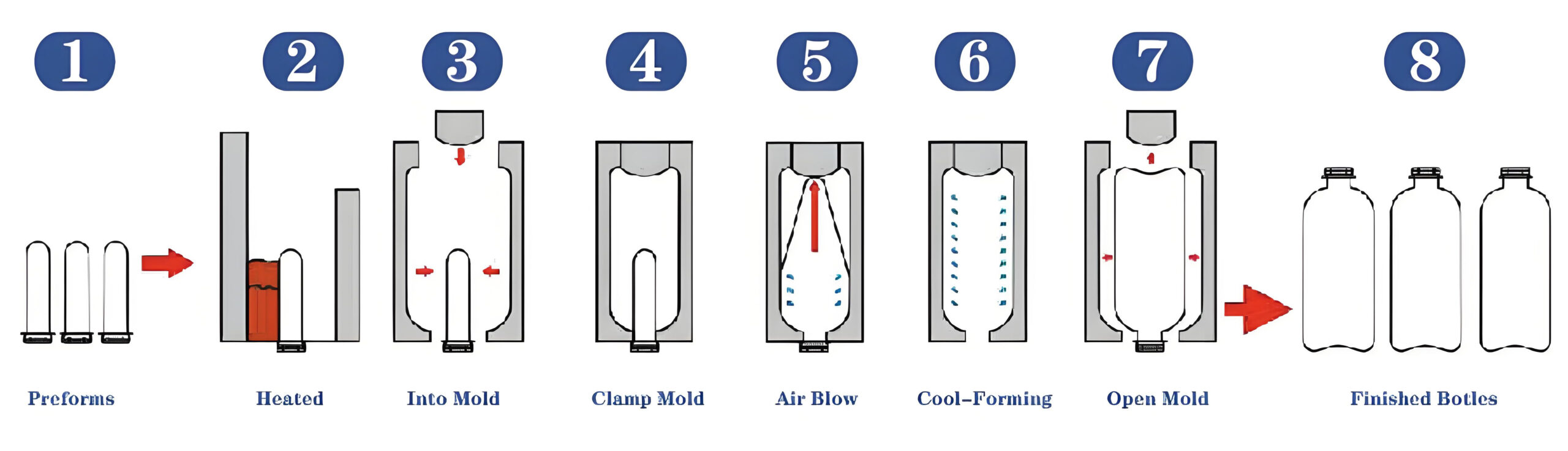

Processing

Energy Saving 40%, Directly Create Profits For Customers.

Bottles