เครื่องเป่าขวด PET แบบอัตโนมัติ

Price

Contact Us For A Quote

บริการหลังการขาย

7*24 Hours

Payment Method

T/T or L/C

Transportation Method

By Sea

Tips: We have many models of machines, and there are also many machine parameters involved. Due to different voltage standards in different countries, we suggest that you can consult us directly online or send us detailed requirements.

Features

High Efficiency: PET blow molding machines use multi-cavity mold designs, allowing the production of multiple bottles in a single cycle, greatly enhancing production efficiency.

Energy-Saving Design: Modern PET blow molding machines are typically equipped with advanced heating systems and energy-saving technologies, effectively reducing energy consumption and lowering production costs.

High Degree of Automation: Most PET blow molding machines are highly automated, capable of automatic feeding, blowing, and ejection, significantly reducing the need for manual operation and improving production efficiency and product quality.

Versatility: PET blow molding machines can accommodate the production needs of bottles of different specifications and shapes, offering great flexibility. Changing molds and adjusting parameters is relatively simple, allowing for quick switches in the production of different types of products.

Precise Control: The equipment is equipped with advanced PLC control systems and human-machine interfaces, enabling precise control of parameters at each production stage, such as temperature, pressure, and time, ensuring consistent product quality.

Compact Structure: Modern PET blow molding machines are designed to be compact, occupying a small footprint, making them suitable for various production environments, especially those with limited space.

Environmental Performance: Many PET blow molding machines consider environmental factors in their design and manufacturing, such as using eco-friendly materials and reducing emissions of waste gas and wastewater, complying with environmental regulations and standards.

Low Noise Operation: Through optimized design and the use of noise reduction technology, PET blow molding machines operate with low noise levels, improving the production environment.

Safety Protection: The equipment is typically equipped with various safety protection devices, such as overload protection and emergency stop features, ensuring the safety of operators.

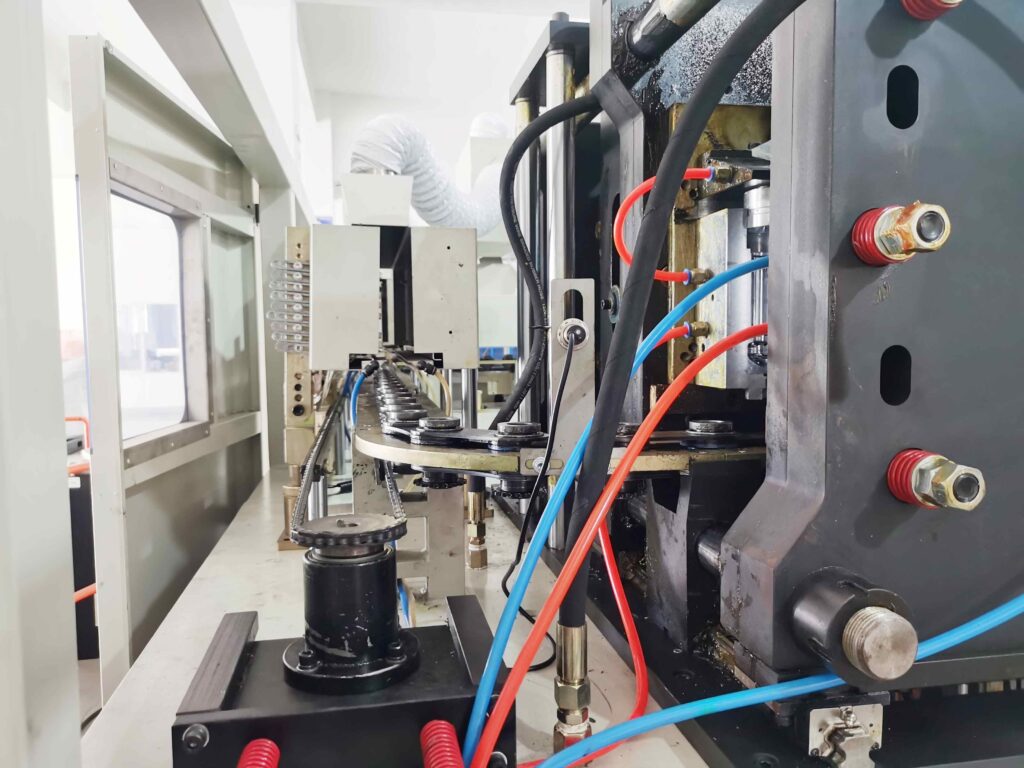

Our Machine

Capacity

| Model | Center Distance | Capacity |

| YDBA-1L-2 | 76.2mm | 1800-2500BPH |

| YDBA-2L-2 | 114.3mm | 1600-2500BPH |

| YDBA-2 | 114.3mm | 1600-2500BPH |

| YDBA-1L-4 | 76.2mm | 4500-6000BPH |

| YDBA-2L-4 | 114.3mm | 3500-6000BPH |

| YDBA-4 | 114.3mm | 3000-5000BPH |

| YDBA-1L-6 | 76.2mm | 8000-9000BPH |

| YDBA-2L-6 | 114.3mm | 10000-12000BPH |

| YDBA-5L | 190.5mm | 500-600BPH |

| YDBA-10L | 190.5mm | 400-500BPH |

| YDBA-20L | 400-500BPH | |

| YDBA-5L-2 | 220mm | 1500-1800BPH |

| YDBA-10L-2 | 1000-1200BPH | |

| YDBA-2L | less than 152.4mm | 1500-2500BPH |

| YDBA-5L | 190.5mm | 1500-2500BPH |

Parameters

| Model | YDB-2 | YDB-2A | YDB-2 (Jars) | YDB-2A (Jars) | YDB-4 | YDB-4A | YDB-6 | YDB-6A | YDB-A5L | YDB-A25L | |

| Host parameters | Number of Cavity (cavities) | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 | 2 | 1 |

| Clamping Force (Kg) | 35000 | 45000 | 35000 | 45000 | 40000 | 48000 | 56000 | 65000 | 65000 | 65000 | |

| Mold stroke (mm) | 90 | 110 | 120 | 110 | 90 | 125 | 90 | 125 | 260 | 320 | |

| Stretch rod stroke (mm) | 300 | 400 | 300 | 400 | 260 | 330 | 260 | 330 | 350 | 460 | |

| Bottom stroke (mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle spacing (mm) | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | 220 | 300 | |

| Number of embryos (pcs) | 66 | 52 | 66 | 52 | 95 | 82 | 106 | 92 | 80 | 48 | |

| Product parameters | Max. capacity (ml) | 600 | 1500 | 600 | 1500 | 600 | 1500 | 600 | 1500 | 6000 | 25000 |

| Max.bottle height (mm) | 260 | 330 | 200 | 330 | 260 | 330 | 260 | 330 | 350 | 460 | |

| Max. bottle diameter (mm) | 68 | 105 | 85 | 105 | 68 | 105 | 68 | 105 | 180 | 230 | |

| Theoretical output (bph) | 2500 | 2000 | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 | 1500 | 400 | |

| Electrical parameters | Number of heating boxes (pcs) | 2*2 | 4*4 | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | 4*4 | 4*4 |

| Number of lamps (pcs) | 2*8 | 4*8 | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | 4*10 | 4*120 | |

| Total power capacity (Kw) | 36 | 50 | 36 | 50 | 45 | 80 | 69.5 | 100 | 82 | 80 | |

| Air source parameters | Work pressure (Mpa) | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing pressure (Mpa) | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | 2.5-3.0 | |

| High pressure air consumption (l/min) | 2.4/30 | 2.4/30 | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | 5.0/30 | 4.8/30 | 4.0/30 | |

| Configuration power (Kw) | 30 | 30 | 30 | 30 | 45 | 45 | 60 | 60 | 60 | 44 | |

| Cooling water | Pressure (Mpa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Rated power (Hp) | 3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 5 | 5 | |

| Dimension | Host size (mm) | 2700*1800*2200 | 3300*1800*2000 | 2700*1800*2200 | 3300*1800*2000 | 3900*1800*2200 | 4800*2200*2200 | 4200*2100*2200 | 5200*2100*2200 | 4000*1800*2200 | 4000*1800*2200 |

| Weight (Kg) | 2000 | 2500 | 2000 | 2500 | 3500 | 4500 | 6000 | 7000 | 4500 | 4500 |

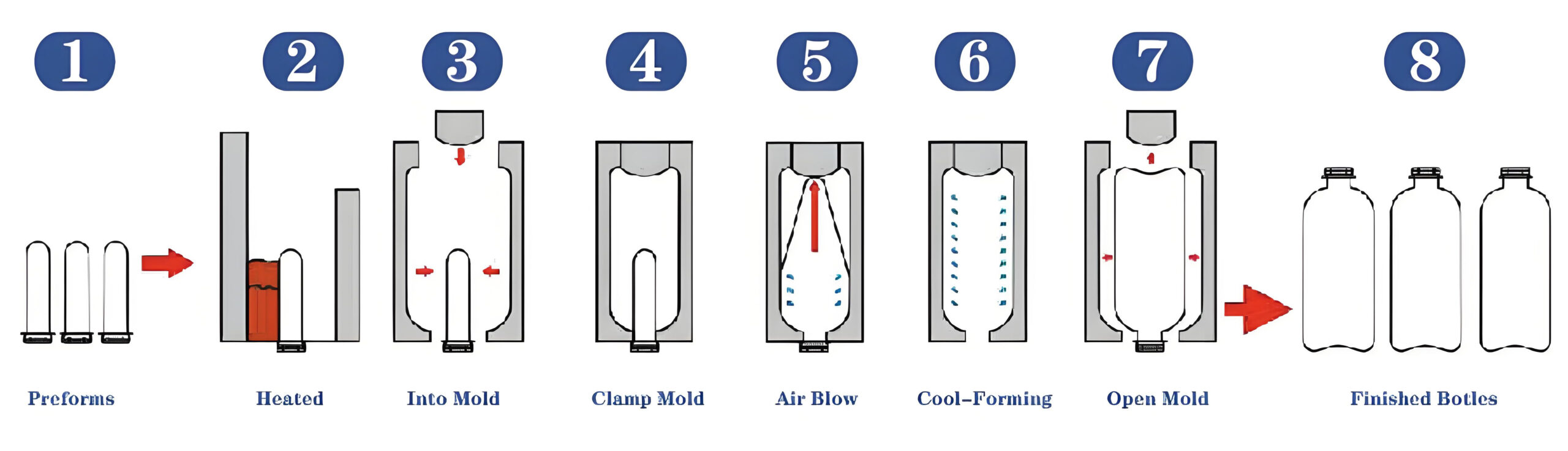

Processing

Energy Saving 40%, Directly Create Profits For Customers.

Bottles