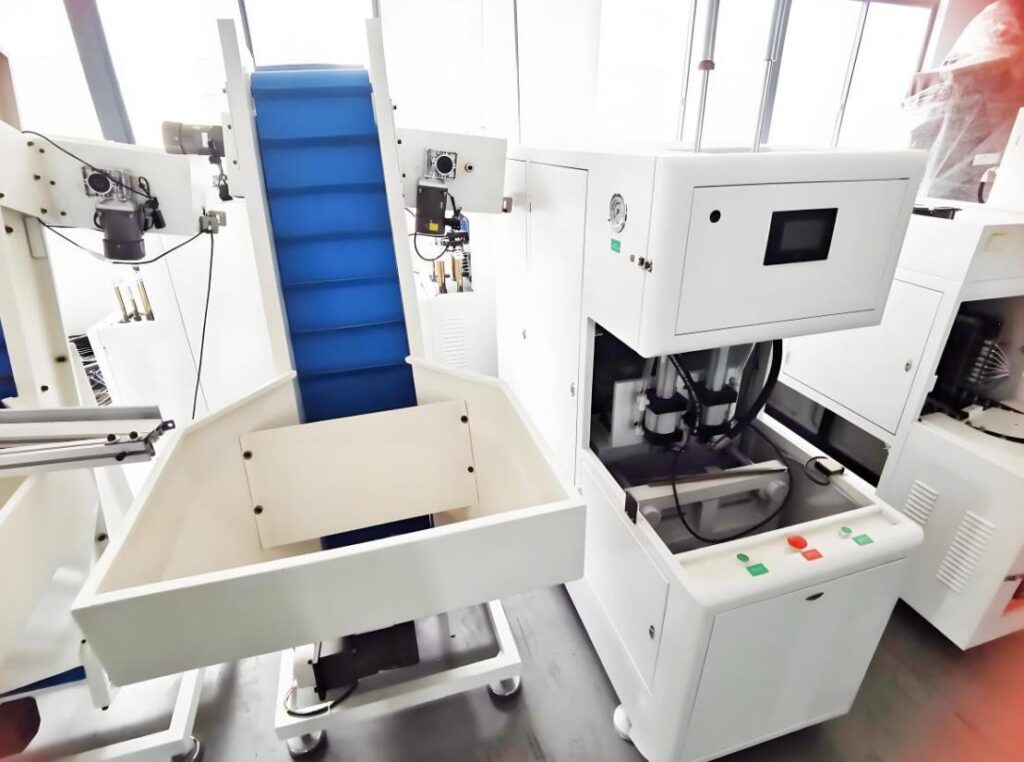

Полуавтоматическая машина для выдува ПЭТ-бутылок

Price

Contact Us For A Quote

Послепродажное обслуживание

7*24 Hours

Payment Method

T/T or L/C

Transportation Method

By Sea

Tips: We have many models of machines, and there are also many machine parameters involved. Due to different voltage standards in different countries, we suggest that you can consult us directly online or send us detailed requirements.

Description

The advantages of semi-automatic blow molding machines in terms of cost, flexibility, and ease of operation make them the preferred equipment for many small and medium-sized enterprises, especially those with low production volumes but requiring flexible adjustments.

Features

- Cost-effectiveness: Compared to fully automatic blow molding machines, semi-automatic blow molding machines have lower procurement costs, making them suitable for small enterprises and entrepreneurs with limited budgets.

- Ease of operation: Semi-automatic blow molding machines are typically designed to be easy to operate, requiring no highly specialized personnel. Simple training is sufficient for production operations.

- High flexibility: Semi-automatic blow molding machines can quickly adjust and change molds, accommodating different sizes and shapes of bottles. This makes them ideal for small batch, multi-variety production.

- Compact footprint: The compact structure of semi-automatic blow molding machines takes up less space, making them suitable for production workshops with limited space, facilitating layout and management.

- Easy maintenance: Due to their relatively simple structure, semi-automatic blow molding machines are easier to maintain and service, with lower maintenance costs, and higher reliability and durability.

- Low energy consumption: Compared to fully automatic blow molding machines, semi-automatic blow molding machines have lower energy consumption, effectively controlling production costs and saving energy.

- Moderate production speed: Although the production speed of semi-automatic blow molding machines is not as high as that of fully automatic equipment, it is sufficient for small and medium-sized production needs, meeting daily production tasks.

- Quality control: Equipped with basic quality control systems, semi-automatic blow molding machines can monitor and adjust key parameters during the blow molding process, ensuring the quality of the produced bottles meets requirements.

- Safety: Our semi-automatic blow molding machines generally come with basic safety features to protect operators from harm during operation, such as protective covers and emergency stop buttons.

Capacity

| Model | Capacity |

| YDB-2L-2 | 700-1000 BPH |

| YDB-2L-4 | 1000-1800 BPH |

| YDB-5L-1 | 400-600 BPH |

| YDB-5L-2 | 400-600 BPH |

| YDB-10L-1 | 250-400 BPH |

| YDB-10L-1 | 100-250 BPH |

Parameters

| Model | YDB-2L-2 | YDB-2L-4 | YDB-5L | YDB-6L-2 | YDB-10L | YDB-20L | |

| Molding | Clamping Force(Kg) | 14000 | 28000 | 28000 | 32000 | 28000 | 32000 |

| Clamping Stroke(mm) | 155 | 190 | 215 | 215 | 280 | 360 | |

| Stretching Stroke(mm) | 370 | 370 | 400 | 400 | 450 | 500 | |

| Cavity Spacing(mm) | 90-130 | 100-110 | 90-130 | 90-120 | 90-120 | 200-300 | |

| Number of Cavity | 2 | 4 | 1 | 1-2 | 1-2 | 1-2 | |

| Carriage Unit(pcs) | 72 | 96 | 72 | 96 | 96 | 19 | |

| Theoretical Output(bph) | 800-1000 | 1600-2000 | 400-1100 | 800-1200 | 300-400 | 80-150 | |

| Electrical System | Heating power(Kw) | 28*0.5 | 32*0.8 | 28*0.8 | 32*0.8 | 28*0.8 | 38*0.8 |

| Numb of Lamp Layers | 7 | 8 | 8 | 10 | 10 | 12 | |

| Air System | Operating Pressure(Kg) | 7-9 | 7-9 | 7-9 | 7-9 | 7-9 | 7-9 |

| Low Pressure Air Consumption(m³/min) | 0.6 | 0.8 | 0.6 | 0.8 | 0.6 | 0.8 | |

| Blowing Pressure(Bar) | 20-30 | 20-30 | 20-30 | 20-30 | 20-30 | 20-30 | |

| High Pressure Air Consumption(m³/min) | 1.2 | 2.4 | 1.2 | 1.6 | 1.6 | 1.6 | |

| Chiller | Operating Pressure(Bar) | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 |

| Temperature Range(℃) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 | |

| Consumption(m³/min) | 1.5 | 1.5 | 1.5 | 1.5 | 2.0 | 3.0 | |

| Flow Rate(P) | 3 | 3 | 3 | 3 | 5 | 5 | |

| Blower Machine | Blower Dimension(mm) | 1580*610*1560 | 1650*810*2100 | 1900*650*1800 | 2000*780*1800 | 1950*650*1750 | 2180*740*1900 |

| Blower Weight(Kg) | 650 | 800 | 750 | 800 | 700 | 1250 | |

| Heater Machine | Heater Dimension(mm) | 1700*565*1335 | 2200*565*1345 | 1700*670*1600 | 2170*670*1600 | 2170*670*1600 | 2650*720*1950 |

| Heater Weight(Kg) | 350 | 400 | 350 | 400 | 400 | 600 | |

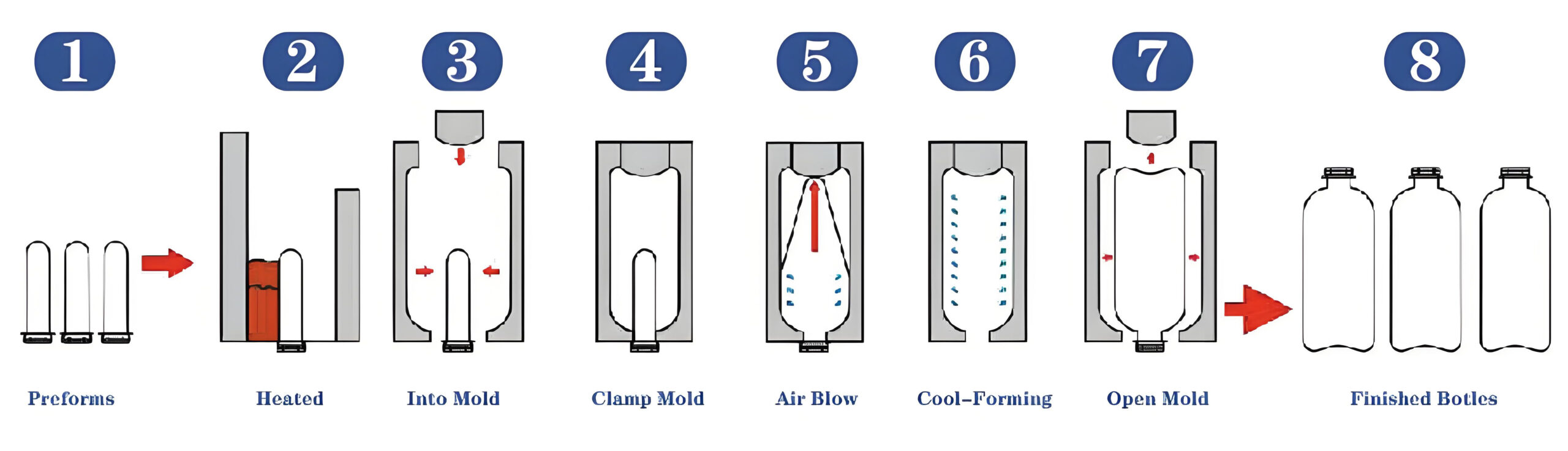

Processing

Energy Saving 40%, Directly Create Profits For Customers.

Bottles