About YuDa

As the top manufacturer of PET bottle blow molding machines manufacturer in China, We can provide different types of PET bottle blow machines according to your business requirements and budget.

20 Years of Experience

We have over 20 years of experience, so you can trust our quality and service. if you want to find a manufacturer who has full experience and good service, feel free to contact us.

Over 60 Countries

In the past 20 years, our injection molding machine has been exported to more than 60 countries. We hope our machine can make our customer’s businesses successful and life be happier.

Top 2 Manufacturer

Our high series full automatic PET bottle blow molding machines with over 20 patents, smaller space, higher capacity, and lower energy consumption. It will help your business be more competitive.

All Series We Can Provide.

If you are looking for a PET bottle-making machine, YuDa can provide you with the best solution, we have the high standard full automatic PET bottle blow molding machines, standard full automatic series, and semi-automatic series.

YuDa Products

Since YuDa establishment, we have been providing customers with high-quality products, solving technical problems in production, and providing high-quality services.

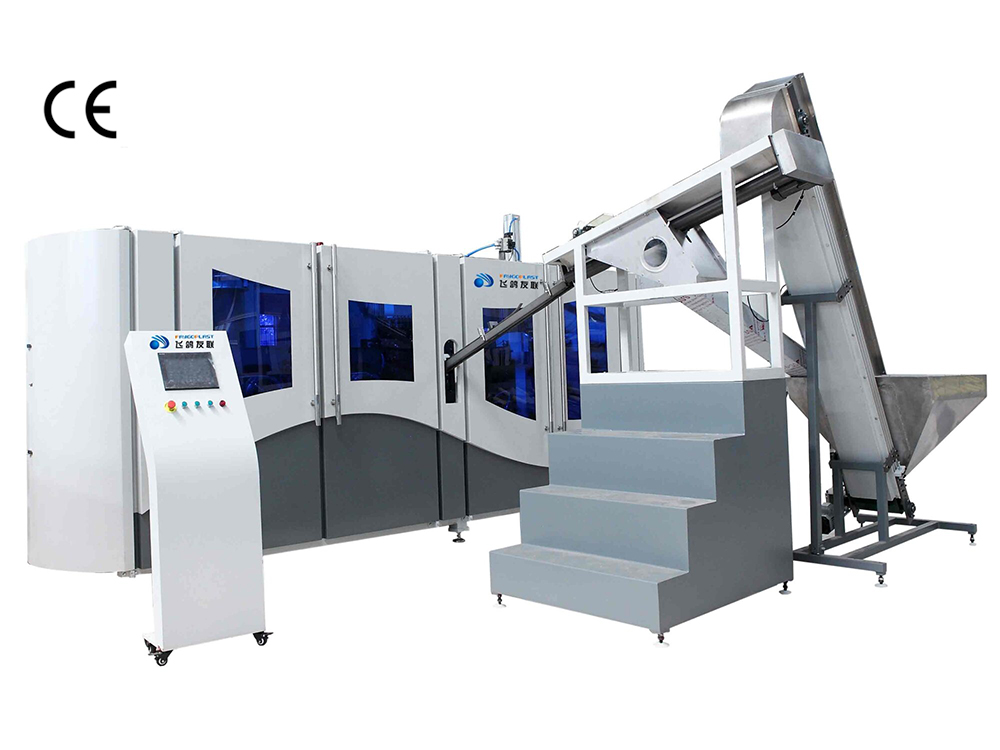

High Speed Series (8000BPH~15000BPH)

High-speed machine FGX series blow molding machine, single-mode speed can reach 2500~3000BPH.

Standard Speed Series (1000BPH~7000BPH)

Modern PET blow molding machines are typically equipped with advanced heating systems and energy-saving technologies.

Semi-auto Series (Good Price, Ready Ship)

semi-automatic blow molding machines have lower procurement costs, making them suitable for small enterprises.

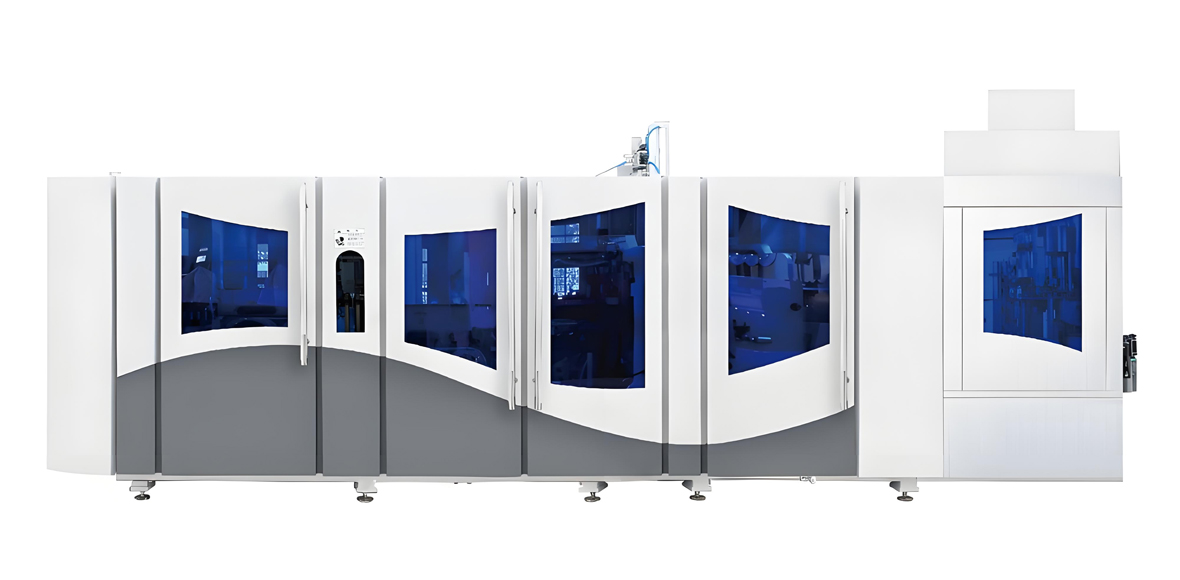

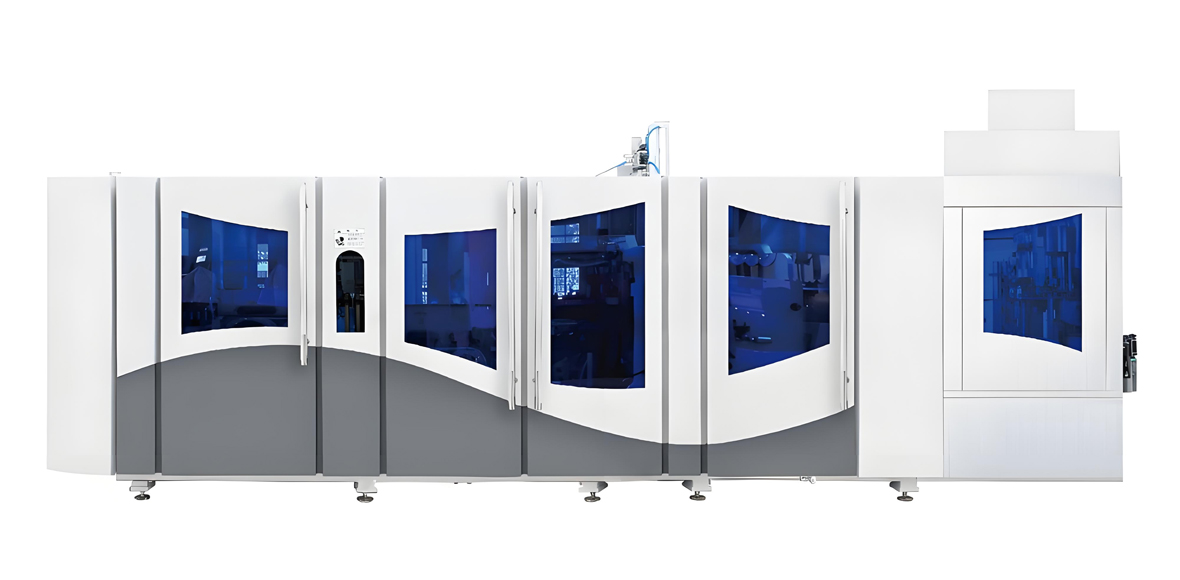

Linear Blowing-Filling-Capping CombiBlock

Our linear blowing-filling-capping combiblock, compact, simple, easy to operate. Specialized in mini linear blowing, filing, capping combiblock, which can save your plant area.

Bottle Blow-Filling-Capping (BFC) Machine

Our Blow-Filling-Capping (BFC) Machine can produce PET bottles while completing the filling of drinking water and other liquids and installing bottle caps.

Why Choose Us

We are a technology-based enterprise that produces, sells, repairs, maintains, and operates bottle blowing machines.

Efficient

The unique cam linking system integratesmold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shortens the blowing cycle.

Monitoring System

Equipped with remote monitoring system, engineers in China headquarter can check the data collected andsent by the PLC anytime with the mobile, feedback will be informed to the client’s site if something abnormal.

Energy-Saving

Heater distance in the heating oven is minimized to 38.1mm, compared with the conventional heating oven, it saves more than 30% electricity consumption.

Modular

The machine adopts modularized design concept tomake it convenient and cost-saving for the maintenanceand changing changeovers.

Mature and Stable

Some of the components on our machine use more mature and stable brands to ensure the stable operation of our machine.

Warm Global Customers With China Plastic Machinery

Let us have the opportunity to provide you with reassuring and satisfying.

Latest Blogs

Share our latest news here.

-

Linear Blowing-Filling-Capping CombiBlock

Our linear blowing-filling-capping combiblock, compact, simple, easy to operate. Specialized in mini linear blowing, filing,…

-

Bottle Blow-Filling-Capping (BFC) Machine

Our Blow-Filling-Capping (BFC) Machine can produce PET bottles while completing the filling of drinking water…

-

Oman FGX-6 High-Speed PET Blow Molding Machine

Date: December 26, 2024Country: OmanMachine: High-Speed PET Bottle Blow Machine (FGX-6)Products: 250ml, 330ml, 500ml Bottles…

Get In Touch

If you are interested in our company and machine, feel free to contact our sales engineer. We will contact you as soon as possible.

Zhangjiagang City, Jiangsu Province, China

008615950512730 (Whatsapp)